Truck and Track

June/July 2017

www.truckandtrack.com8

BUSINESS NEWS

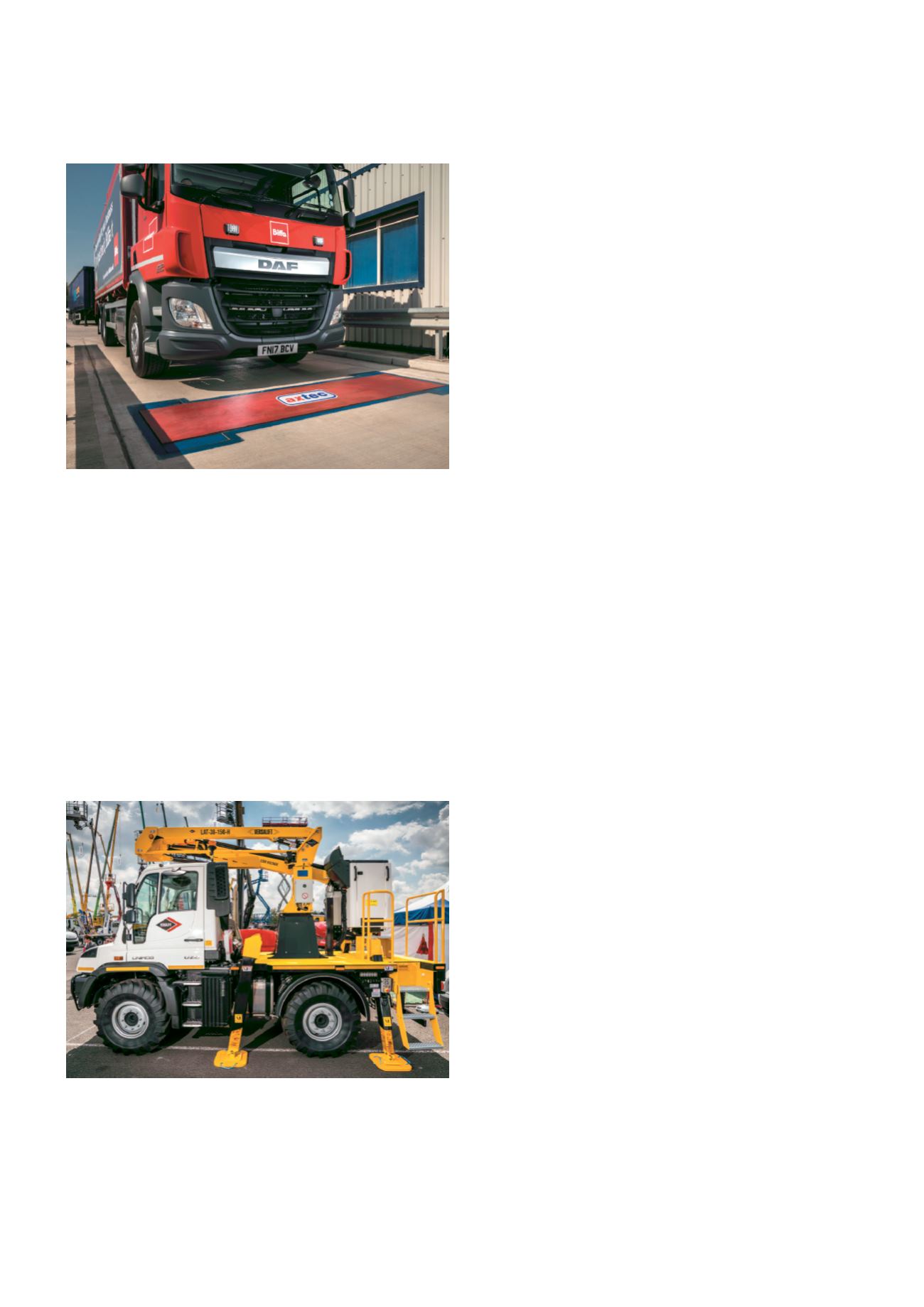

Ford & Slater, one of DAF Trucks’ largest UK dealer groups, has

reported annual savings of £19,000 since installing Axtec’s

drive-over dynamic weighbridge at its headquarters in

Leicester. Axtec’s dynamic weighbridge can check all six axles

of a tractor / trailer combination, plus gross vehicle weights, in

just 40 seconds and is themost accurate of its type in the world

(to within +/- 0.25%).

Ford & Slater, which previously incurred the costs and time

penalties of weighing off-site, was prompted to invest in Axtec’s

dynamic weighbridge after learning of the same equipment being

installed at Leyland Trucks in Lancashire – the UK assembly plant

for right-hand-drive DAF vehicles.

Mark Chater, Account Manager at Ford & Slater, was full of praise:

“We’ve used Axtec equipment for five years now, and I can certainly

vouch for the excellent quality and reliability with our existing

Axtec onboard load indicators.

“We knew Leyland Trucks had installed their own Axtec dynamic

weighbridge, so we were comfortable that the equipment had

the right credentials. It appeared on paper to be a safe investment

for us. And so it has proved, with £19,000 annual savings and,

just as importantly for our customers, a significant reduction in

downtime.”

Derek Hack, Sales Manager at Runcorn-based Axtec, commented:

“Traditional plate-type weighbridges do provide accurate gross

vehicle weights, but, increasingly, hauliers need to check individual

axle weights as well. Our dynamic weighbridge solution does

exactly that, and it does it very quickly and very accurately. The

cost benefits over public weighbridges, as Ford & Slater has clearly

demonstrated, can be significant.”

Axtec is stated to be the UK’s only dedicated weighbridge

manufacturer, specialising in the design, build, supply and

installation of axle and vehicle weighing equipment. From its

Runcorn HQ, Axtec designs, builds and installs its dynamic and

static weighbridges, alongside its new onboard axle load indicator

(for van, rigid and articulated vehicle applications) and portable

weigh-pads.

Axtec produces a range of dynamic, static, onboard and

portable axle weighing solutions. If you’re interested to catch

up on the latest axle-weighing issues, follow Axtec’s Derek

Hack on Twitter (@Derek_Axtec) and read his latest blogs at

http://axleweighing.blogspot.co.uk/. www.axtec.co.uk www.fordandslater.co.ukAxtec dynamic weighbridge checks

individual axle weights

Truck-mounted access platform leader Versalift and the team

responsible for the Mercedes-Benz Unimog in the UK have

joined forces to launch a new model. Based on a Unimog U218

implement carrierwithnominal 7.5t grossweight, it isdesigned

to provide utility companies with a compact, fast and reliable

off-road vehicle for work on low-voltage power distribution

lines in difficult-to-reach areas, typically the repair of storm-

damaged lines or clearance of obstructing foliage.

An official bodybuilding partner of Mercedes-Benz Trucks, Versalift

is the world’s largest vehicle-mounted platform manufacturer: its

UK operation, based at Kettering, Northants, claims a domestic

market share of almost 90%.

The Mercedes-Benz Unimog is renowned for its combination of on-

road speed and all-terrain capability. The new vehicle is fitted with

an all-steel boom and platform that offers a maximum working

height of 15m. The equipment is insulated to safeguard operatives

working on lines carrying up to 1000 volts – crucially, should the

boommake contact, the chassis is also protected.

Given the demanding conditions inwhich the Unimog is likely to be

deployed, Versalift has opted for the sturdy reliability of traditional,

fully hydraulic boom operation. However, in the unlikely event that

the team using the truck run out of diesel, an electronic override

ensures that the platform can be brought down safely.

Other features of the design include an exceptionally lowcentre-of-

gravity, enhancing offroad stability, and very little overhang behind

the back axle, which makes for excellent departure angles. The

Unimog’s panoramic windscreen is also an aid to drivers having to

negotiate rough terrain.

The U218 variant is powered by an advanced and economical

130 kW (177 HP) four-cylinder engine, whilst 4WD provides the

ultimate in traction when the going gets tough.

www.mercedes-benz.co.uk/unimog http://versalift.co.ukUnimog nowwith Versalift platform for

powerline access