www.truckandtrack.com

www.truckandtrack.com

June/July 2017

Truck and Track

55

DANGEROUS GOODS

TheFinnishmarineenginemanufacturer

Wärtsilä

Corporation

has

been

contracted to provide equipment and

maintenance for the FSRU (Floating

Storage Regasification Unit) and LNG

carrier vessels of Oslo-based operator

Höegh LNG A/S.

Two new 170,000 m

3

LNG carrier vessels

being built for Höegh LNG at the Samsung

Heavy Industries (SHI) and Hyundai Heavy

Industries (HHI) shipyards in South Korea

will each be powered by fourWärtsilä 50DF

dual-fuel engines. There is an option for a

further three vessels in the SHI series.

The two vessels will also feature the

latest Wärtsilä regasification technology

to operate as FSRUs. The regasification

solution to be supplied to these vessels

represents Wärtsilä’s latest development

in the field.

It is based upon the use of seawater and

glycol as the intermediateheatingmedium,

a lighter and less space-demanding

alternative than earlier systems with a

propane-based heating system. By using

seawater as opposed to steam-heated

solutions, the CO2 emissions are notably

reduced. Furthermore it will be delivered

as a complete module, thereby making

installation easy.

Under

a

new

five-year

technical

management agreement, Wärtsilä will

provide support for eight ships of the

company’s existing fleet, as well as for

its two new vessels currently under

construction. The services of the technical

management agreement includeCondition

Based Maintenance (CBM) to optimise the

availability, reliability and performance of

the Wärtsilä engines.

Included are maintenance planning and

advisory services involving the combined

technical expertise of Wärtsilä and Höegh

LNG specialists. The customer will have

access too to Wärtsilä’s extensive global

service network.

“Our

longstanding

relationship

with

Höegh LNG is again strengthened by this

supply of our state-of-the-art engines

and regasification systems, as well as

the technical management agreement

that will ensure optimal performance of

the company’s entire fleet,” asserts Cato

Esperø, Sales Director of Wärtsilä Norway.

Øivin Iversen, CTO of Höegh LNG, remarks:

“We have confidence in Wärtsilä as a

provider of well designed and engineered

solutions, and are pleased with the choice

of a strong provider as regards the engines

and regasification systems.”

GormHillgaar, Senior Vice-President – Fleet

Management at Höegh LNG, emphasises:

“The technical management agreement

is also very important. Wärtsilä’s CBM

service enables excellent predictability of

the engines’ condition and maintenance

requirements, which is of great value to our

operations.”

Wärtsilä has delivered and commissioned

numerous floating LNG regasification

plants based on either closed or open loop

regasification technology. Wärtsilä has

also provided modularised regasification

plants for jetty installations. These

facilitate a much shorter construction time

compared to conventional land-based LNG

regasification terminal projects.

www.wartsila.com/gbr www.hoeghlng.comLatest Wärtsilä LNG

regasification technology

aids Höegh carriers

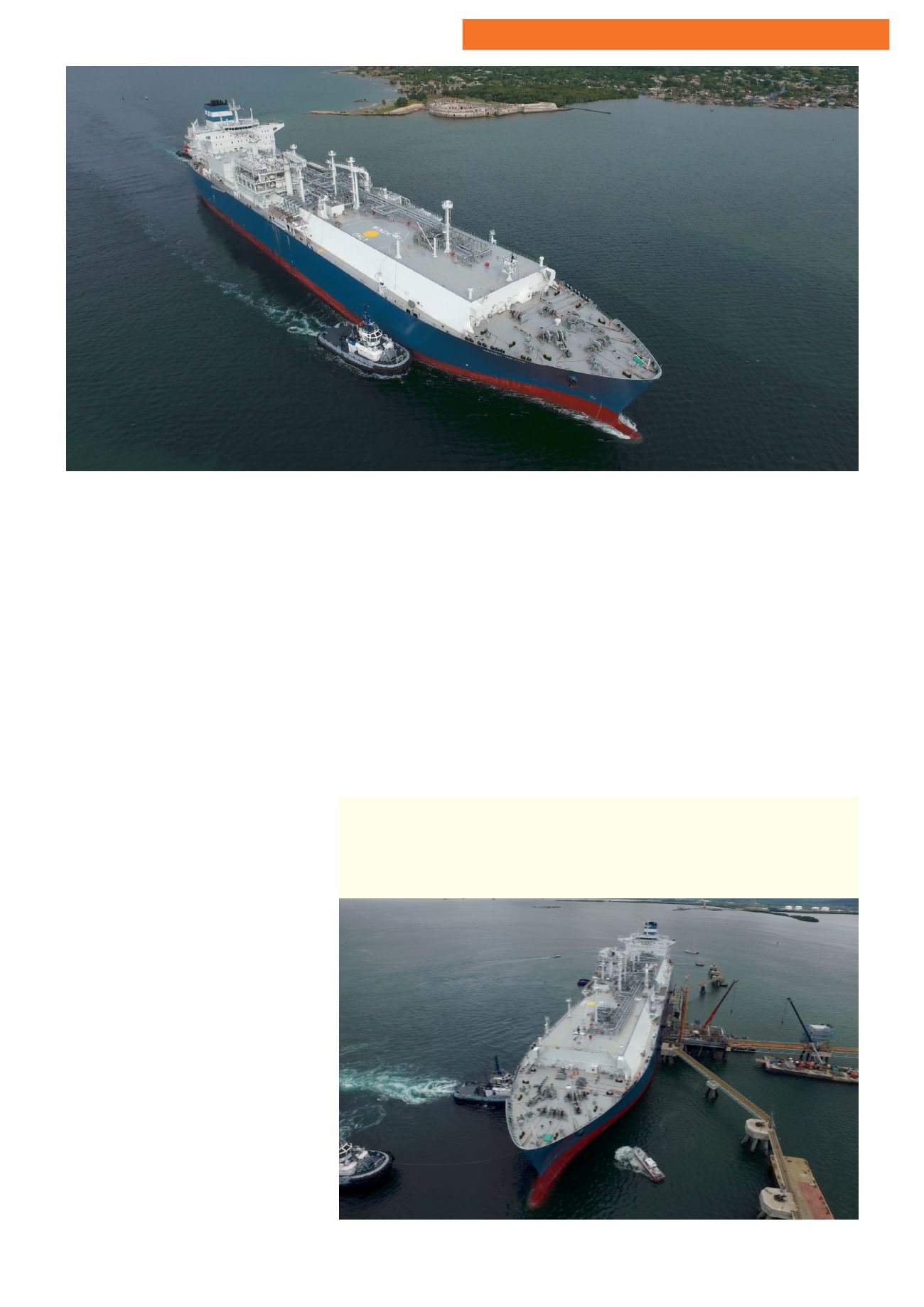

The new LNG tanker Höegh Grace has a deadweight of 82,258 tonnes (gross tonnage 109,844)

The Alfa Laval company Framo AS of Bergen, Norway

(www.framo.com) has signed a contract with Höegh LNG for the

delivery of pumping systems to their new FSRU described above. The contract is for one unit, with an option for three

more units which are currently being built, as noted, at Samsung Heavy Industries in South Korea. By using an onboard

regasification unit, the liquid gas carried by the LNG tanker is converted to gas prior to being brought ashore. This

process requires the gas to be heated, and for this heating large quantities of seawater have to be pumped in. Framo

is to install four pumps in each of the vessels which are due to be delivered during the period 2019 to 2021. A similar

solution has been successfully delivered to Shell’s Prelude FLNG (Floating Liquefied Natural Gas) facility.

The Höegh Grace