Truck and Track

June/July 2017

www.truckandtrack.com50

SAFETY & SECURITY

Unisto has been providing solutions

for the transport industry for

decades and has one of the widest

ranges

of

security

seals

and

accessories available anywhere in

theWorld.

Why should I seal my vehicles?

Security sealing is a method of access

control: it provides a clear indication of

whether the load has been accessed,

which is why these products are often

termed

indicative

seals.

There are two main reasons to use seals. The first is to protect

the load from theft. If you are using a plastic seal, this focuses on

internal theft, i.e. access to the load by transport yardworkers or the

driver when in transit to the delivery point. The second is to protect

your drivers from suspicion.

Mistakes happen when loading vehicles and, once sealed, any error

– an overlooked carton left behind in dispatch, for example – cannot

be blamed on the driver when it is discovered to be missing at the

delivery point. Most honest drivers welcome the use of a security

seal, as it puts their integrity beyond doubt and directs the spotlight

of accountability where it belongs.

So what sort of seal should I choose?

The variety of security seals on the market is huge, and their quality

varies agreat deal. Themost important featureof aplastic indicative

seal is that it cannot be opened and then resealed without leaving

clear evidence.

So who checks plastic seals for tampering?

This is a key point: if

nobody is going to check the seals, thenwhy use one at all? I’ll come

to the checking of seals later on. Here are some elements to look out

for when choosing plastic seals:

■■

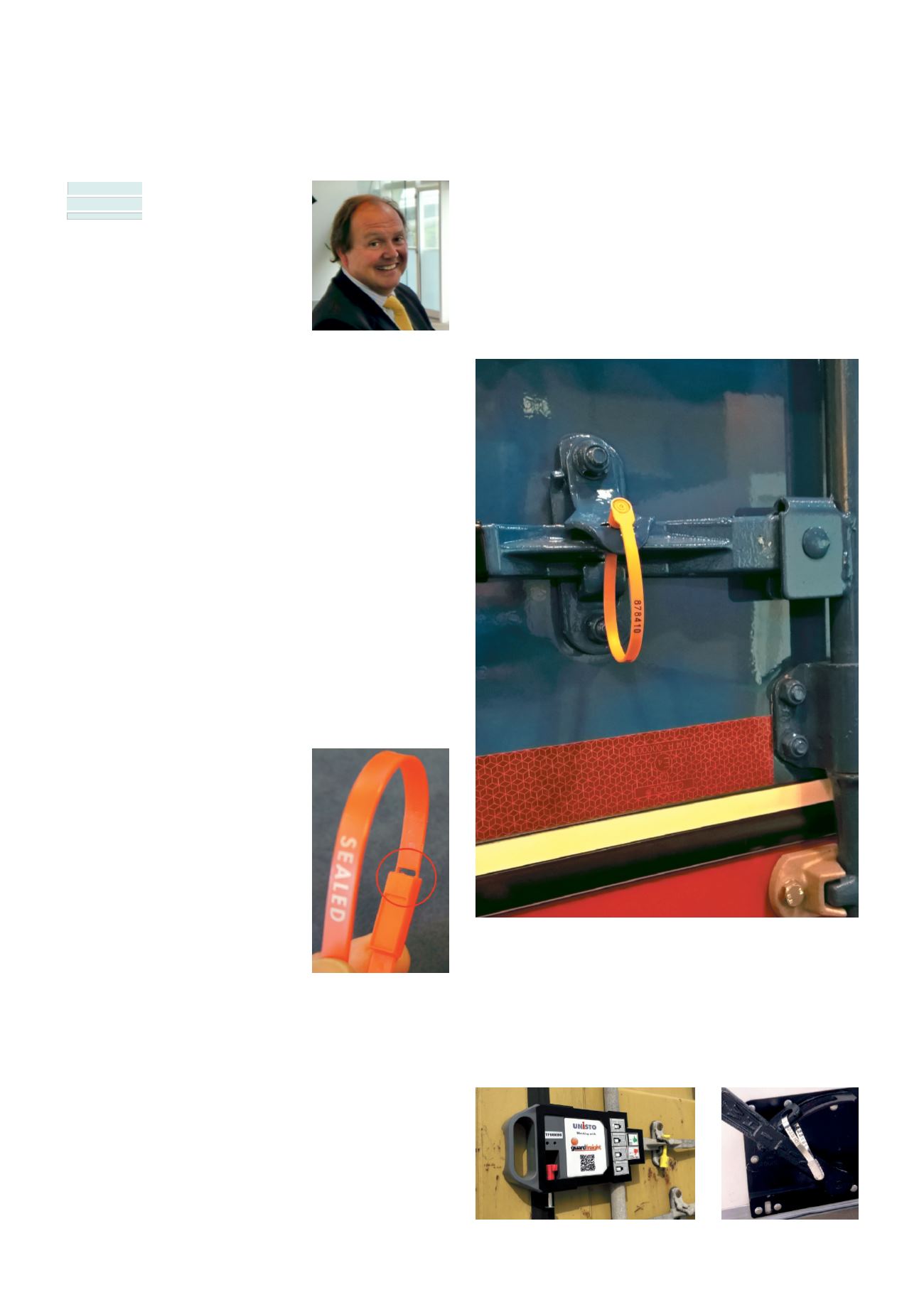

The weak “break point” should be

clearly visible outside the locking

housing (see Fig.1).

■■

Freemovement should be observed

within the locking chamber when

the seal is closed. This shows that

the seal has not been superglued

or heat-welded into place after

tampering.

■■

The quality of the injection

moulding must be clean and clear

of plastic flashings that make

the seal look messy and make

tampering more difficult to detect

on inspection.

■■

The seal must be clearly marked

and numbered, and the numbering easy to read and compare to

the number on the manifest. Bear in mind that numbers can be

changed (a 0 to a 9 for example) or obfuscated, especially when

they were fairly illegible in the first place!

The first two of these elements are only available on fixed-length

seals and for transport use on roller shutter, barn doors or TIR

cords. That is the only type of plastic indicative seal we would

recommend.

An alternative to a fixed-length, tamper-evident plastic

seal would be a reusable electronic seal, where the device is

permanently affixed to the trailer or van door and uses a cable

hasp or magnetic sensors to detect openings.

Thebenefit of a reusable seal is that it avoids theneed for continuous

management (purchasing, control, issuing and disposal) of single-

use seals.

Plastic indicative seals should be used in conjunction with a

padlock, if the vehicle is to be parked up overnight or while your

driver takes a break, to prevent opportunists breaking in whilst the

truck is unattended. Alternatively, use a barrier-type steel bolt or

cable seal which is impossible to remove by hand.

Security seal management & checking regime

Always purchase your security seals from a reputable source. There

is an ISO Standard for security seal suppliers that ensure seals

are manufactured, documented and distributed under complete

control. ISO17712 came about after the 9/11 outrage, when US

Homeland Security looked at more effective ways of controlling the

supply chain into the USA. They realised that security sealing was

open to abuse by unscrupulous and low-quality manufacturers,

Fig 1: Break-point on outside of

locking housing

“

Best practice in security sealing

Expert advice to guide our readers fromDonald Miller, Sales &Marketing Director of the security seal

manufacturer Unisto Ltd

DonaldMiller

The Unisto E-Containerlock senses its environment &

alerts management to changes to a load in transit

Flatstar