www.truckandtrack.com

www.truckandtrack.com

Summer 2019

Truck and Track

45

PORTS

Bristol’s huge lift

World’s largest crane delivered

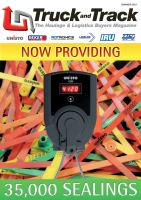

Bristol Port’s key role in the logistics supply chain for the multi-

billion pound construction of Hinkley Point C was showcased last

month as it took delivery of the largest crane in the world.

The machine is destined to undertake all the heaviest lifts required

at Hinkley, making it one of themost critical pieces of infrastructure

in the creation of Britain’s first nuclear power plant in more than

20 years.

Built last year in Belgiumby Sarens, the SGC-250 crane was divided

into modules and shipped to Avonmouth Dock from Ghent. It will

be stored at the Port until it makes the short onward journey to the

construction site in Somerset.

Once reassembled, the crane, which Sarens say is the “mightiest in

the world in both size and capacity”, can handle at a 50m radius an

astonishing 5,000 tonne load – the equivalent of 32 single-storey

houses or 1,600 cars.

Miles Adams, Commercial Manager of

Bristol Port, said:

“The safe delivery, storage and onward

travel of this critical infrastructure

highlights the important role that Bristol

Port plays as a muster point for Hinkley. We

are proud to be a key hub in the logistical

supply chain for one of the largest building

projects in Europe over the next 10 years,

and sea transport is a very efficient and

clean way to move very heavy items; in this

instance from Belgium into Bristol.”

The crane was unveiled by Sarens last year

and its first use will be at Hinkley, where it

is expected to be onsite for four years. The

SGC-250 has a maximum load movement of 250,000 tonnes. Its

main boom can be extended from 118 to 160 metres and the jib

can be extended up to 100 metres, providing height of up to 250

metres or a radius of 275metres. Critically, it has a unique ability to

relocate from one lifting position to another – an engineering first.

When it was launched last year, Sarens said the SGC-250 was

inspired by the “increasing trend” towards modularisation, with

clients prefering to pre-assemble large portions, or modules, in a

controlled environment and then transport and lift them into their

final position.

Bristol Port has itself invested in new cranes to meet the ongoing

demands of the Hinkley project, including its partnership with

Hanson, which is expected to see more than a million tonnes of

aggregate brought through the port destined for the new power

plant. The Port has also earmarked land for the storage of Abnormal

Indivisible Loads (AIL) equipment, that is too big to move on the

motorway network and therefore will be taken down to Hinkley by

barge.

Bristol Port is exhibiting at Multimodal on stand 6020.

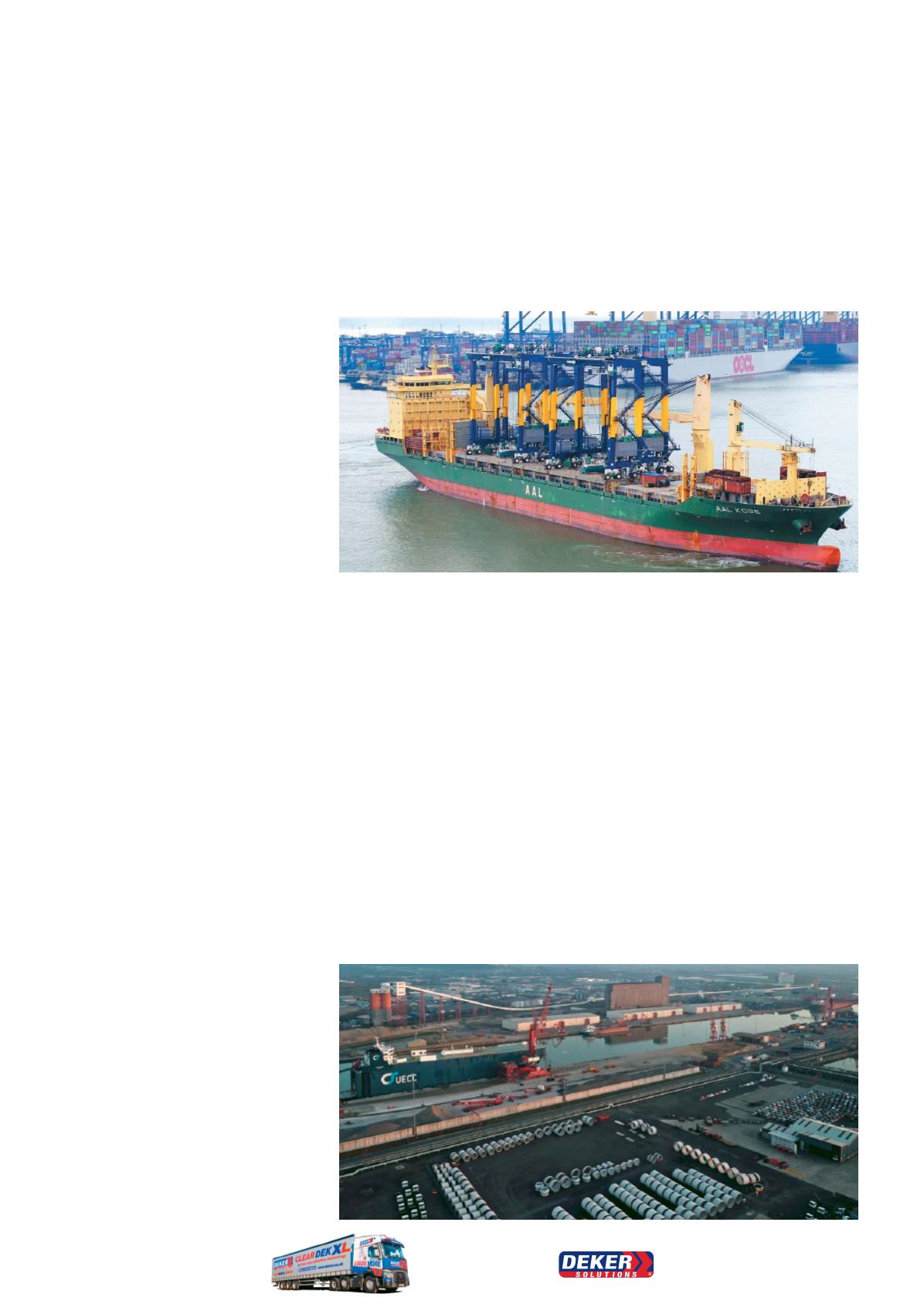

Remote controlled RTGS at the

Port of Felixstowe

Hutchison Ports’ Port of Felixstowe has taken delivery of its first

remote-controlled Rubber Tyred Gantry Cranes (RTGS).

The four electric-powered cranes were built by ZPMC in Shanghai

and are the first of eight similar machines to be delivered over the

next few weeks. The port also has two remote controlled ship-to-

shore gantry cranes currently undergoing manual testing before

being deployed in full remote mode.

Commenting on the latest equipment,

Robert Ashton, Operations Director at the

Port of Felixstowe, said:

“The new cranes represent an important

step towards a greater degree of remote

working at the Port of Felixstowe. Remote

working will deliver benefits for both our

employees and our customers.

“For the drivers, the ergonomics are much

better than a traditional operation. The

physical stress to a driver’s back, neck and

shoulders will be significantly reduced

and the vibrations experienced as cranes

operate will be eliminated altogether.

Operationally, we will be able to deploy

equipment more dynamically to meet

peaks in demand and locating operators,

vessel controllers and supervisors closer to one another will lead to

improvements in alignment and communication.”

The new RTGs will serve Berths 8&9 where an additional 18,000

TEUof container storage has been created tomeet growing demand

at the UK’s leading container port. The new cranes are electric-

powered and capable of stacking containers 6-high to enable more

efficient use to be made of the new yard area.

COMBINED

TRUCK & TRAILER

SOLUTIONS

01543 420 121

www. deker .co.uk